Winning Plastics Accelerates Orders by up to 70 Percent with d.velop sign

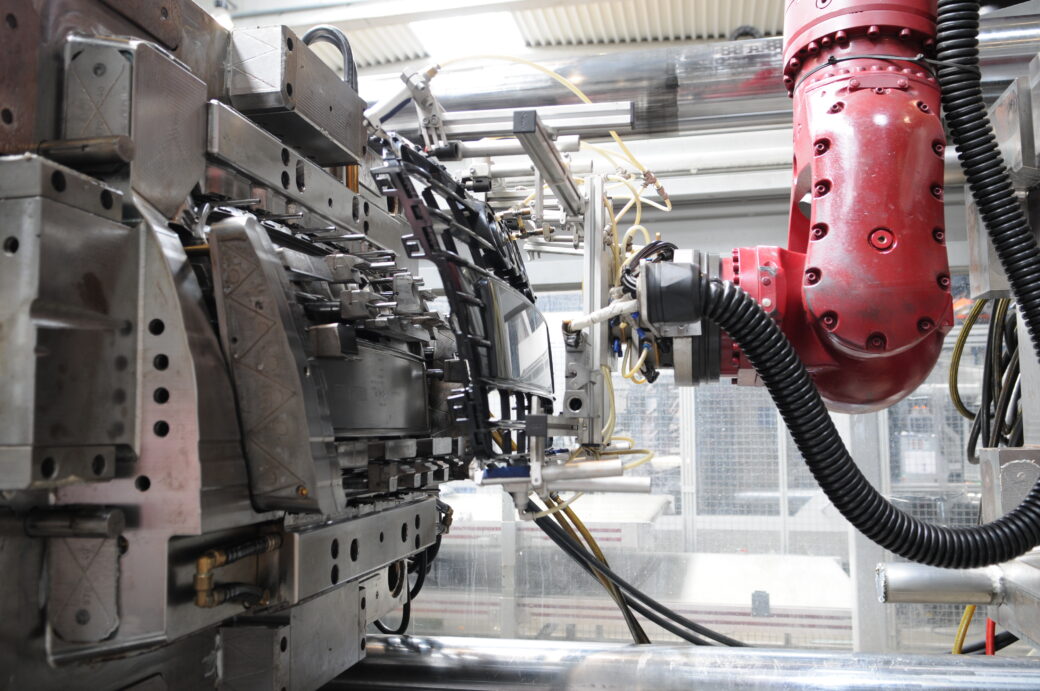

The Bolta-Werke GmbH in Diepersdorf near Nuremberg had a history of 100 years until the semiconductor crisis in 2021 put the entire automotive industry in distress. Clients withdrew, revenues plummeted, and insolvency loomed. However, the German-Czech Winning Group acquired Bolta-Werke, resulting in the preservation of production sites in Gottmadingen and Gütersloh, along with retaining all 700 employees. The company was renamed “Winning Plastics – Diepersdorf.” Core products include plastic parts for cars and trucks.

Winning Plastics’ clients are well-known in the industry: DAF, BMW, Porsche, Skoda, and Volkswagen, among others. In this sector, both excellent quality and innovations are crucial. However, a company is more than its products, and those looking to optimise processes and reduce costs, have more opportunities than just focusing on the manufacturing process.

Digital Signature

Product

1258

Employees

Automotive

Industry

Up to Six Employees Had to Sign an Order

With over 700 suppliers and more than 5000 orders per year, the procurement department faced a significant workload. “Every order had to be printed, filed, and checked using the four-eyes principle,” describes Jochen Birkmann, Head of Materials Management at Winning Plastics. “This used to take a lot of time. Sometimes we even had to run through the entire company to get all approvals.” Depending on the complexity of the purchase, up to six employees had to sign off on the process – such as the specialist department, controlling, the operations manager, procurement, and others.

In 2021, Birkmann and other colleagues realised that the procurement process could not continue this way. “We wanted to digitise it, print less, and avoid waiting for signatures.” Searching for a suitable software solution for digital signatures quickly led the company to d.velop sign from d.velop AG, as the team had already had good experiences with the document management system d.velop documents.

Winning Plastics, then still Bolta-Werke GmbH, also approached other providers of digital signature software. However, the decision favoured d.velop sign. Birkmann explains, “The main reason was that we already had the foundation with d.velop documents in-house. We inquired with other suppliers, but the comprehensive package that d.velop could offer convinced us. The combination of digital signatures and digital archiving, which we already had, was the deciding factor.”

Every order had to be printed, filed, and checked using the four-eyes principle. This used to take a lot of time. Sometimes we even had to run through the entire company to get all approvals. Thanks to d.velop sign, the process is now up to 70 percent faster, and the digitised process is extremely simplified. We hardly have to print anything anymore and save about 80 percent paper. I can only recommend the software.

Jochen Birkmann

Head of Materials Management

Winning Plastics

Diepersdorf GmbH

5,000 Digital Signatures per Year with d.velop sign

Winning Plastics uses around 5,000 digital signatures per year, almost all for commercial contracts such as orders. This also enables a low-threshold method of legitimisation; users work based on their internal identification in the system. Externals can also use d.velop sign, but the current focus is on internal users. Winning Plastics saves time not only through the signature process but especially through the digitised workflow.

“Thanks to d.velop sign, the process is now up to 70 percent faster,” Birkmann describes. This results from the elimination of paper. Users store, for example, who needs to review and approve (or reject) which processes by when in the software. “This is a crucial point,” says Birkmann. “Previously, we had to bring the documents to different departments, like the team leader or workshop manager. Today, the digital workflow takes over.”

6 steps to the introduction of an electronic signature

In this webinar, you’ll learn how we can successfully introduce the electronic signature in the organisation using six steps – from understanding the benefits to getting started with d.velop sign.

Agenda

- Why should I introduce a digital signature?

- d.velop sign as e-signature of the d.velop platform

- 6 Steps to introducing an e-signature

- Next Steps: How we get started digitally together

Start with just one click.

Digital Workflow Reduces Workload and Prevents Errors

For example, if someone was on a business trip, a folder with documents waiting to be signed had to stay on the desk. “Days, in extreme cases,” says Birkmann. With d.velop sign, employees can also sign on the go, such as from a tablet or smartphone. The colleague who originally processed the order enters into the system who must approve each process. The order of signatures is also flexible – either sequentially or all in parallel.

And if a digital signature takes a bit longer: “I can see in the order status who has already signed and who has not,” says Jochen Birkmann, “and we also use reminder emails.” No training for d.velop sign was necessary; after a brief introduction, Winning Plastics employees could start using it in the same year, 2021. “We hardly have to print anything anymore,” says Birkmann, “and save about 80 percent paper. I can only recommend the software. d.velop AG has really met our needs. So far, I must say, we have had no outages and no problems. It just runs over the cloud.”

Savings Potential with d.velop sign for Winning Plastics

- Work hours for printing, circulating, and tracking orders and approvals

- Printing costs

- Maintenance costs for printers

- Costs for paper, postage, envelopes, office supplies, couriers

- Work time for tracking which document is in which processing status with which colleague

Software Demo

Learn More About d.velop Software

Request your personalised live demo of the d.velop software with just a few clicks. Get a live demonstration of the software and ask your questions directly. Simply fill out the form and we will get back to you.