Procurement is a key component of business management. An optimised procurement process can help reduce costs, increase delivery reliability, and improve overall company performance.

What Are Procurement Processes?

Definition: Procurement Process

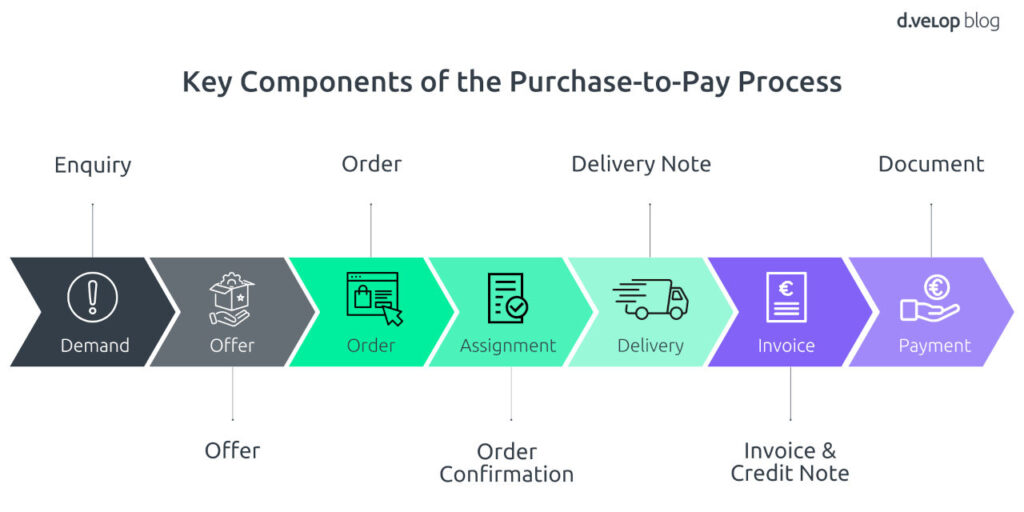

A Procurement process (also known as Purchase-to-Pay processes) include all activities related to planning, purchasing, handling of ordered goods, and payment. They ensure that a company is supplied with goods and services in a timely and cost-effective manner.

Distinction from Related Terms

Procurement = Purchasing?

The terms “procurement” and “purchasing” are often used interchangeably, but there is an important distinction. Procurement encompasses all steps required to obtain the necessary goods or services – from determining requirements and selecting suppliers to tracking deliveries and ensuring quality.

Purchasing, on the other hand, focuses primarily on the actual buying process – placing orders and negotiating terms with suppliers. In this sense, purchasing is a subset of procurement, covering the financial and contractual aspects of acquiring goods and services.

Procurement Processes and Supply Chain Management

While procurement processes focus on the acquisition of goods and services, supply chain management (SCM) covers a much broader scope.

SCM refers to the management of all activities along a product’s entire value chain – from sourcing raw materials and production to delivery to the end customer.

Procurement processes are therefore a part of supply chain management, which aims to optimise the entire supply chain and streamline logistics. In effective supply chain management, procurement is just one of many elements working together to control the value chain and ensure that products are delivered on time and in a cost-efficient manner.

What Types of Procurement Processes Are There?

In general, there are various procurement processes that companies can use to ensure a steady supply of goods and services. The choice depends on the specific needs of the organisation. The most common types of procurement include single (or spot) procurement, stock procurement, and just-in-time procurement.

Single Procurement

With single procurement, goods or services are purchased only when an actual need arises. This method allows for high flexibility but can result in higher costs, as bulk discounts are usually not available.

Stock Procurement

Stock procurement involves purchasing materials in larger quantities to build up inventory. This allows companies to benefit from lower prices and better availability in the long term. However, it requires precise inventory planning and carries the risk of overstocking.

Just-in-Time Procurement

In just-in-time procurement, materials are delivered exactly when needed. This approach minimises storage costs and reduces the risk of obsolete stock. However, it requires accurate planning and strong relationships with reliable suppliers to prevent delivery delays.

Each method has its advantages and disadvantages. The choice of the most suitable procurement strategy should be based on the company’s individual requirements, market conditions, and long-term business objectives.

How Do Procurement Processes Work?

The procurement process typically begins with the identification of needs and continues through budgeting, supplier selection, and ordering. It concludes with goods receipt and payment processing.

Here’s an overview of the key phases in the procurement process:

- Needs Identification: This phase involves determining which goods or services are required within the company. An (electronic) purchase requisition (PR) is created to specify the exact requirements.

- Quotation: Suppliers are contacted to provide quotations for the requested products or services.

- Purchase Order: Once a supplier is selected, a formal purchase order is issued and sent to the supplier.

- Order Confirmation: The supplier confirms receipt and acceptance of the order, along with the agreed terms and conditions.

- Delivery: The ordered goods or services are delivered by the supplier.

- Invoicing: The supplier issues an invoice for the goods or services delivered.

- Payment: The company settles the invoice according to the agreed payment terms.

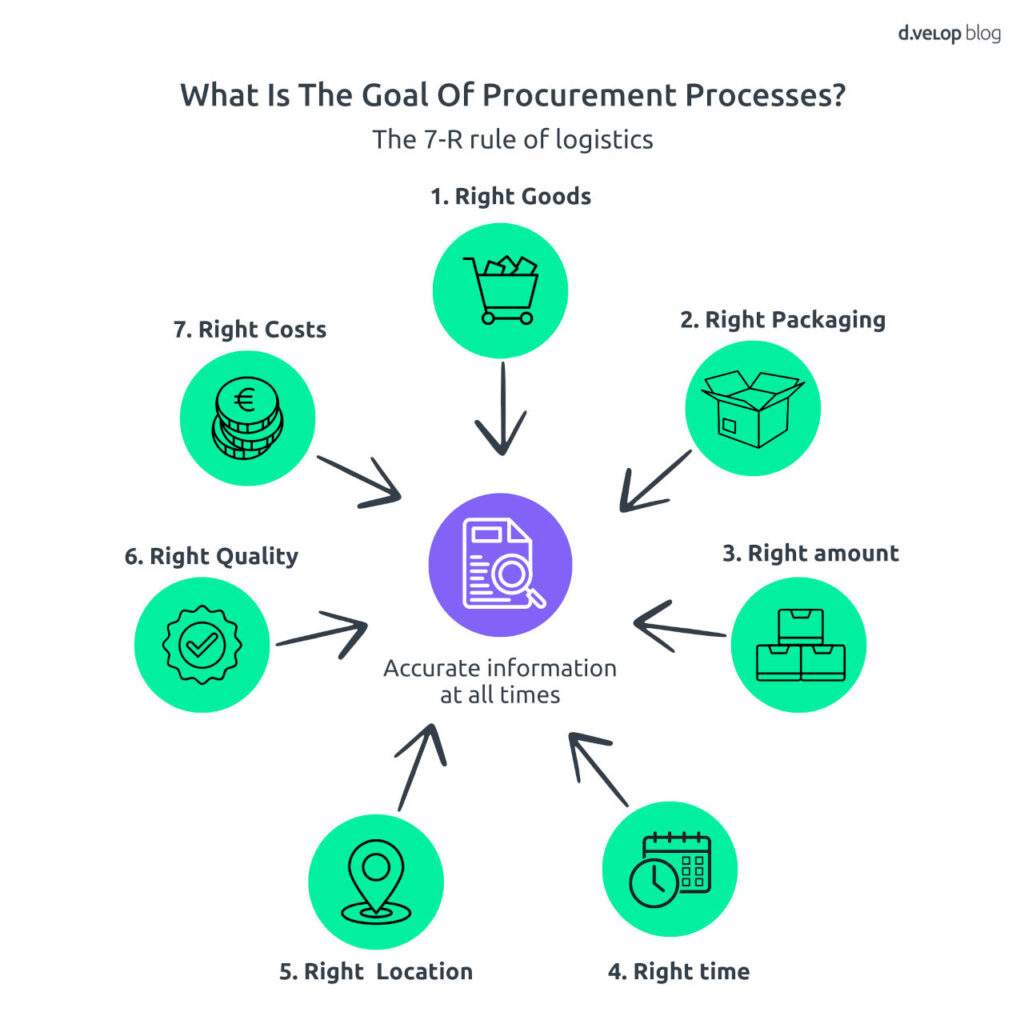

What Is the Goal of Procurement Processes?

The goal of procurement processes is one of the first guiding principles taught to apprentices and students in logistics management:

To procure the right goods, in the right quantity, in the right packaging, at the right time, to the right place, in the right quality, and at the right cost.

- Right Goods: Ensuring that the required products are sourced in the correct specifications.

- Right Quantity: Ordering the exact amount needed to avoid overstocking or shortages.

- Right Time: Deliveries must arrive at the scheduled time to avoid disrupting operations.

- Right Place: Goods must be delivered to the correct location – e.g. a warehouse or directly to production.

- Right Quality: The quality of the goods must meet the company’s standards and requirements.

- Right Cost: Procurement should be cost-efficient without compromising on quality.

- Right Packaging: Goods must be delivered in appropriate and secure packaging.

Procurement processes should be designed to be as efficient as possible, enabling the acquisition of high-quality goods at the lowest possible cost. The key to achieving this lies in the optimisation of procurement processes.

What Are Typical Pitfalls in the Procurement Process?

There are several common pitfalls in the procurement process that can pose challenges for businesses:

- Maverick Buying Effect:

Unauthorised purchases made outside of established procurement guidelines, leading to unnecessary costs and inefficient processes. - Inadequate Demand Planning:

When actual needs are not accurately assessed, resulting in overstock or supply shortages. - Lack of Transparency:

Makes it difficult to track orders and deliveries, increasing the likelihood of delays and errors. - Inaccurate Supplier Selection:

Choosing the wrong supplier can lead to issues with quality, pricing, or delivery terms. - Poor Communication:

Misunderstandings between departments or with suppliers can significantly hinder the procurement process.

These issues often arise when the core competencies of the procurement department are overlooked. Continuous optimisation of procurement processes helps to avoid such pitfalls, making the process more efficient and cost-effective.

Why You Should Optimise Your Procurement Process

Even a relatively simple procurement process involves a wide range of stakeholders within a company – from employees raising the initial request, to supervisors and the procurement department. As a result, even minor inefficiencies can have significant consequences. There are many compelling reasons to optimise your procurement process:

- Increased transparency and control across all ordering procedures

- Better terms and purchasing prices

- Reduced process costs

- Securing early payment discounts and avoiding late payment fees

- Minimisation of overall process expenses

- Audit-proof storage of process-related documents

Purchasing as a Growth Driver – Dr. Christoph Feldmann

Whereas purchasing in the past was primarily valued for cost savings, it can now actively shape a company’s growth and future viability.

Dr. Christoph Feldmann

Chief Executive Officer of the Federal Association for Materials Management, Purchasing and Logistics (BME)

With these words, Dr. Christoph Feldmann describes the changing role and perception of purchasing within companies. The new opportunities for purchasing are closely linked to the concept of Purchasing 4.0 in many areas. Digitalisation has significantly transformed the traditional view of purchasing.

Although the benefits seem obvious, many companies fail in their projects. Often, they simply lack the right entry point to get started. Yet, beginning is easier than expected.

Process Automation: Step-by-Step to an Optimised Procurement Process

Analyse of the Current Situation as a Starting Point

Strategy before tactics. Always! Before you start getting bogged down in individual problems without a clear plan, you should take the necessary time to gain a clear overview of your procurement processes.

Without asking the right questions, it is difficult to identify errors and potential for optimisation. Talk to colleagues. Be self-critical. Question processes that have “always been done this way.” Compare ideal scenarios with actual needs. Some questions you should ask yourself before optimising your procurement process include:

- Are goods ordered by various departments/employees within the company, or is there a central purchasing function?

- Are there uniform procurement guidelines established within the company?

- Is there an approval process for orders in place?

- Does the company use an electronic procurement process?

- Do employees make use of your trusted suppliers/supplier portals and the associated terms?

- Do you have a clear overview of all invoices currently outstanding at any time?

A Few Steps to Automated Procure-to-Pay Processes in SAP

Gain insight into what a digital procurement process looks like and its benefits over the traditional process.

Outlining Target (To-Be) Processes

To successfully establish target (To-Be) processes, it is advisable to proceed step-by-step:

- Define Objectives:

First, the main objectives of the future process should be established. These goals may include increasing efficiency, reducing costs, preventing errors, or improving collaboration. Clear objectives provide direction and help focus on the key points. - Involve Stakeholders:

All relevant departments and employees affected by the new processes should be actively involved. Their expertise is essential to develop realistic and practical target processes. - Outline Process Steps:

The necessary steps in the optimised process must be defined. Bottlenecks or inefficient workflows in the current process should be identified and improved through automation or simplification. - Select Technology and Tools:

Choosing appropriate digital tools or software solutions is crucial. These should be compatible with existing systems and enable automation of tasks. - Set Metrics:

KPIs (Key Performance Indicators) help measure the success of the new processes and continuously monitor progress. These metrics allow for targeted adjustments if necessary. - Create Process Documentation:

A detailed documentation of the target process is important to ensure that all parties understand and correctly implement the new procedure.

These steps help not only to optimise the target process theoretically but also to practically integrate it into the company’s structure.

Selection and Implementation of Suitable Technologies

The selection and implementation of suitable technologies is a crucial step on the path to digitalisation and process optimisation within a company. It is not just about deploying modern procurement software, but about choosing systems that are compatible with each other and meet the company’s specific requirements. The right combination of technologies ensures seamless flow of data and information between different platforms and departments, leading to increased efficiency and improved collaboration.

An example of such an effective combination is the integration of d.velop software with SAP and Microsoft SharePoint. While SAP serves as a powerful ERP system forming the basis for many business processes, SharePoint enables efficient document management and collaboration. The d.velop software ensures that these two systems communicate with each other and optimise business processes. This allows companies to consolidate procurement-related information from SAP and SharePoint into a single system, simplifying work across various sources and saving time.

Blog Series on the Purchase to Pay Process in SAP

We have dedicated an entire blog series to the Purchase to Pay (P2P) process to show companies using SAP how our software can support the entire P2P cycle. The series covers everything from explaining Maverick Buying, through examining the individual sub-processes of the P2P process (SAP purchase requisition, SAP goods receipt, SAP invoice verification, SAP archiving), to exclusive insights into the software.

💻Book Software Demo

Experience the power of d.velop’s software with a personalised live demo, easily requested with just a few clicks. Watch as the software comes to life before your eyes and ask any questions you may have in real-time.