Why should industrial companies strive for paperless production? This question is being discussed more and more frequently in manufacturing companies and leads to discussions between internal stakeholders. They are often aware of the advantages of paperless production, but many companies find it difficult to actually implement it. Although a number of digital technologies are available today to replace paper-based processes, the introduction of robust solutions and products to optimise processes is still not common practice.

But how exactly can digital and paperless production be implemented? In this blog article we provide examples and solutions that replace paper-based processes in production and lead to an increase in efficiency.

Relevance of paperless production for manufacturing companies

Every industrial company should pursue the goal of shortening information paths and at the same time making documents available to every employee with one click, regardless of time or location. However, a wide variety of documents (e.g. work instructions, QM documentation or defect recordings) are often distributed throughout the company by manual postal distribution . In the worst case, unnecessary copies and different versions of the documents are created, which leads to errors in order entry, work preparation, production and assembly. This means that not only does the actual process suffer, but ultimately the quality of the products also suffers. This paper-based process not only has the disadvantage of long waiting times, but also a lack of transparency, a lack of traceability and a loss of quality. Companies are a long way from an integrated way of working and short lead times.

How can this be avoided?

Paperless production cannot be implemented overnight. Individual process steps should be gradually digitised so that in the long term, all data and documents for a process are made available in digital form. The switch to paperless production does not mean simply continuing correspondence via email or Excel lists, but rather implementing a holistic, automated, digital solution across all areas of the company.

Create flexibility and secure competitive advantages through paperless production

The conversion from paper-based to paperless production affects not only corporations, but also small and medium-sized industrial companies. In order to continue to be able to respond flexibly to customer requirements and remain competitive, production companies must ensure a fast and efficient process chain. In times of increasing digitalisation, both customers and employees expect transparency and holistic access to information at all times. The digitisation of document-based business processes is critical to ensure a centralised data pool. This allowing all documents to be made available to all operatives of course, based upon a secure access permission structure.

Advantages of paperless production

- Greater contribution to sustainability

- Cost savings because less paper is required

- More flexibility

- Shorter lead times

- Traceability of individual process steps

- Media-free working method

- No dusty or dirty documents

Examples of the path to paperless production

An ECM system as the foundation for the digitalisation of production

As part of paperless production, the manufacturing industry is particularly faced with the challenge of managing and controlling large amounts of data and documents. ECM software (Enterprise Content Management) offers a solution here by supporting companies in the management of documents and processes. Such software can be used for a variety of tasks in the manufacturing industry, such as controlling manufacturing processes, monitoring quality standards, and documenting suppliers and customers.

The advantages of ECM software in the manufacturing industry are obvious. Companies can manage their documents and processes centrally, achieving greater efficiency and productivity. In addition, documents and data can be found and used more easily, facilitating collaboration between different departments and teams.

There is also the possibility of automating business processes. With the help of workflows, processes such as releases or approvals can be controlled automatically. This leads to greater efficiency and faster turnaround times.

Another important benefit of ECM software is improving compliance. By centralising and controlling documents and processes, ECM software can help companies comply with legal requirements and quality standards.

By using such software, companies can improve their document and process management, facilitate collaboration between departments and teams, automate business processes and improve compliance. Companies that invest in ECM software can increase their competitiveness, invest in paperless manufacturing and prepare for the future.

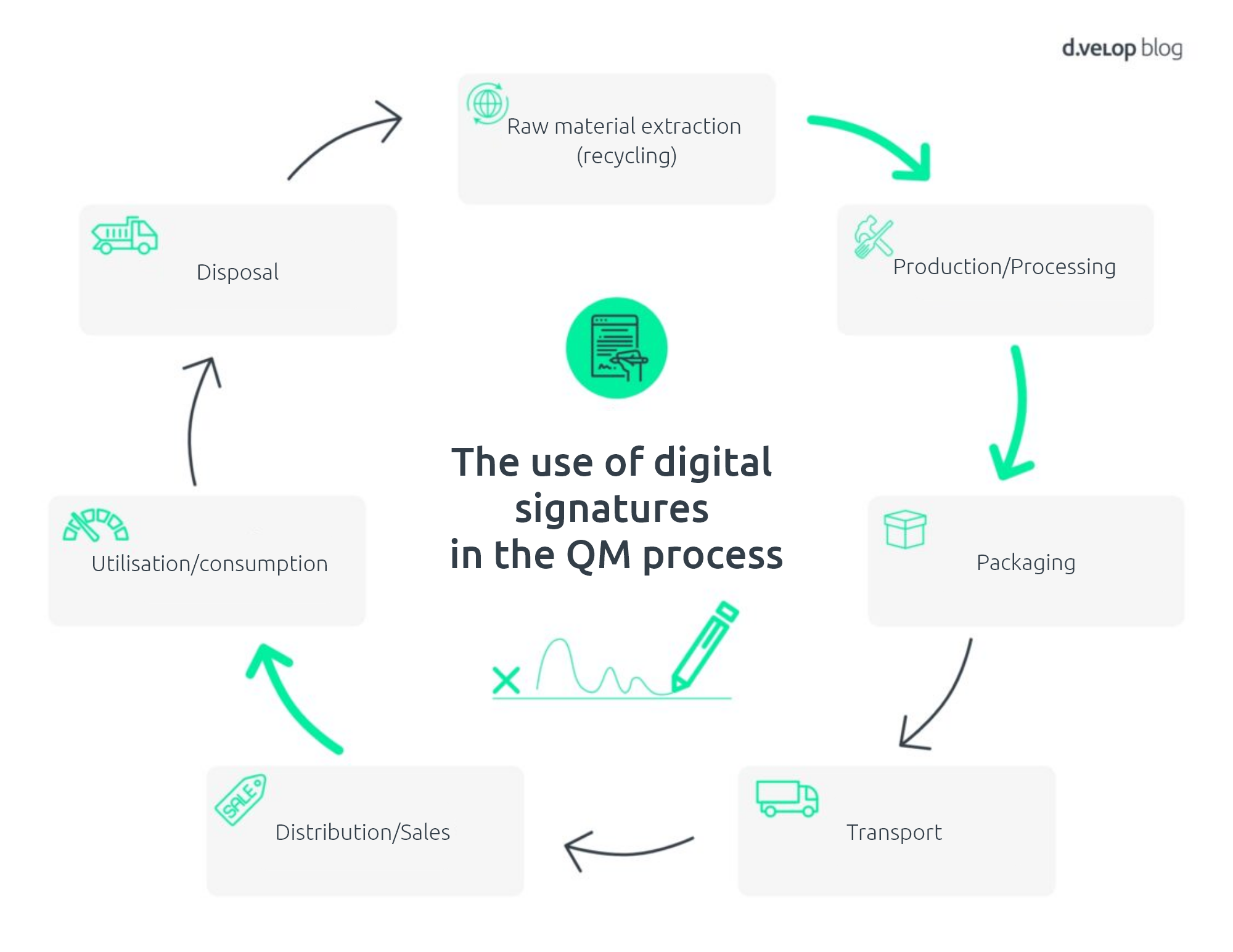

Paperless QM documentation thanks to digital signatures

As part of the quality management process, a large number of documents are often generated (e.g., work and procedural instructions, handover protocols or transport documents). The documents are often still passed back and forth between the different departments on a paper basis. A solution on the way to paperless production can be paperless QM documentation including a digital signature. This means that signature processes are carried out digitally and paper costs reduced significantly. In addition, fast processing times are guaranteed, the signature status can be continuously viewed and waiting times can be avoided through digital handover.

Sign documents digitally – anywhere and anytime with d.velop sign

Graphic shows the use of the digital signature in the QM process as part of lean production

Digital delivery of documents to avoid printing and postage costs

Deliver production documents, business letters, invoices or pay slips digitally? Here, too, there is often still potential for optimisation in industrial companies. With a digital mailbox, all types of documents can be encrypted and delivered to customers, employees or partners in a legally secure manner with proof of delivery (including 2-factor authentication). Printing, enveloping and delivering documents by post can be a thing of the past and digital mail delivery represents another step towards paperless production. GEKA GmbH (leading manufacturer of brushes and innovative, high-precision applicators in the cosmetics and skin care industry) is also already benefiting from the advantages of the digital solution.

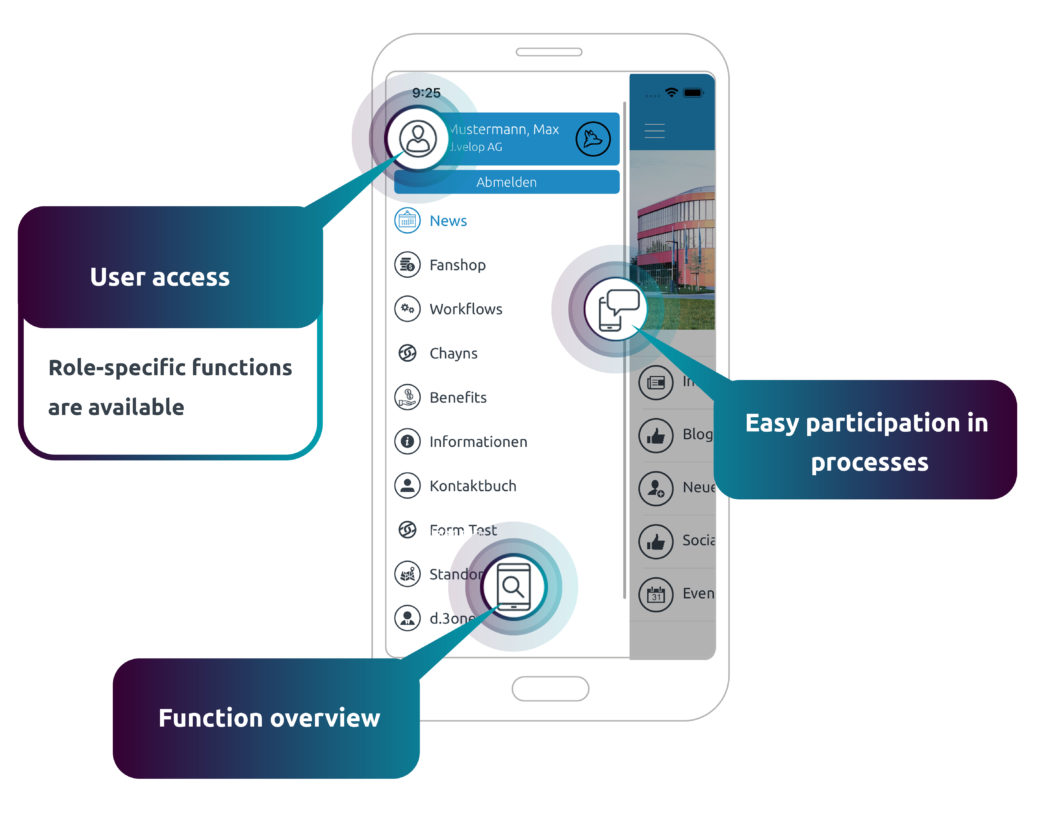

Digital employee communication via app

A central factor in paperless production is internal communication between employees in administration and production, which can also be made paperless. For example, communication processes and workflows can be presented more transparently, quickly and cost-effectively with an employee app as a holistic communication solution for a company. Process steps that can be done via the employee app:

- Provision of production protocols

- Providing maintenance schedules and safety protocols

- Provision of work instructions (e.g., QM documents)

- Provision of emergency plans and machine instructions

- Online procurement applications

- Digital vacation requests and approvals

- Digital sick note

- Approvals of facility use

- Digital damage reports

- Personnel requirements planning

If you consider that one employee alone prints an average of 0.68 trees per year, the digital provision of the above-mentioned documents makes a comprehensive contribution to sustainability and paperless production.

Employee Self Services in the d.velop community connect app

- Requirements for paperless production

- ERP software

- Central data management (e.g., with a document management system)

- Provision of digital devices

- Stable LAN or WLAN structure