Who doesn’t know it? You’ve ordered something, but the package hasn’t arrived or is delayed. This can cause discomfort on the one hand and on the other hand, lead to customer attrition. Therefore, the shipping process requires a structured approach to ensure that the right product is in the right place at the right time.

Definition of the Shipping Process

The shipping process is the crucial link between logistics and distribution, enabling the transport of goods from the merchant to the customer or the destination.

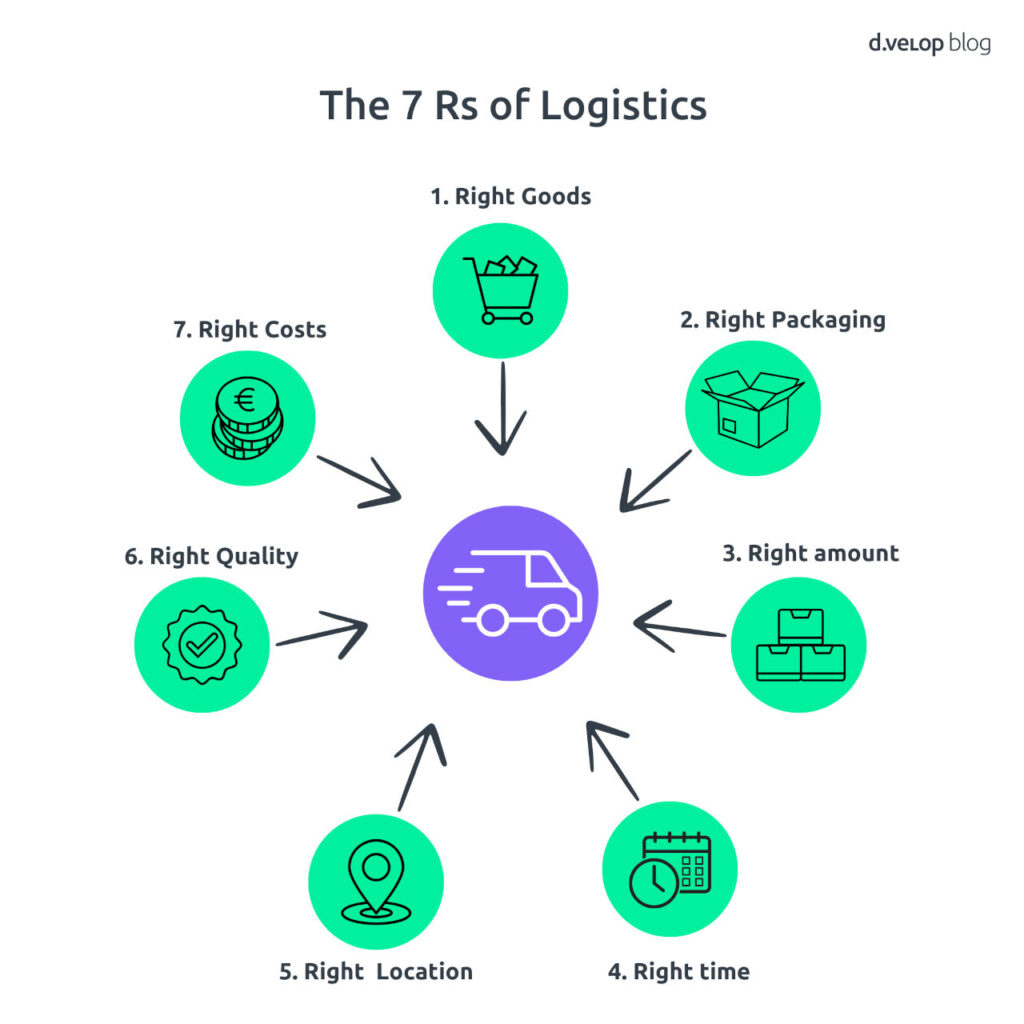

Shipping Process — The 7 Rs of Logistics

The 7 Rs of logistics are well known. They describe a logistical aspect that must be implemented “right” in order to satisfy customers, save costs, and optimise the process.

Logistics means ensuring the availability of the right goods, in the right quantity, in the right condition, at the right place, at the right time, for the right customer, at the right cost.

Seven rights definition according to Plowman

Providing products at the right time and place can pose challenges. Not all companies have multiple locations where they produce or store goods, which can result in long distances to the customer. Another issue can be cross-location communication. Despite these challenges, it must be ensured that information is available at all times about the stage of the shipping process the goods are in and how long delivery will take.

The 6 Steps of the Shipping Process

To meet the requirements of proper logistics, the six steps in the shipping process must be adhered to, ensuring that the goods are properly packaged, ready for shipment, and delivered to the correct destination.

The typical steps of the shipping process are as follows:

- Order Processing:

When the order arrives, it must be checked, and then an acknowledgment of receipt must be sent. Prior to this, inventory checking must be carried out to ensure that the ordered products are available. - Packaging and Labelling:

Next, the goods must be packaged with the appropriate materials according to shipping requirements. Then, a shipping label or other identification marking must be attached. - Shipping Preparation:

In the third step of the shipping process, shipping is prepared by creating the necessary documents, such as delivery notes, invoices, or customs documents. Additionally, the mode of transportation must be chosen, and an appropriate shipping service provider must be selected. - Shipping and Tracking:

Once the shipment has been handed over to the carrier or logistics company, it is equipped with a tracking number to monitor the estimated delivery time. - Delivery and Receipt:

Upon delivery of the shipment, the sender receives a confirmation of receipt, and the goods are checked for completeness and possible damage. - Returns and Customer Service:

Returns of goods or exchange processes may occur in the final step of the shipping process. Therefore, customer service should be available to assist with delivery or product issues, as well as returns.

How can the shipping process be quickly and easily optimised?

Shipping processes occur in almost all areas of the private sector. Accordingly, every company requires an efficient, error-free process: from order confirmation to delivery. This is best achieved through digital support. For this purpose, a Document Management System (DMS) provides the perfect foundation. In a DMS, all necessary documents can be stored in one tool. This speeds up and simplifies document and information management. The d.velop DMS features AI-driven document recognition and classification, as well as a collaboration tool for working on documents simultaneously. Additionally, it is integrable with many system landscapes, and other solutions such as workflow management, such as d.velop process studio, can be easily linked.

Simplification and Automation of the Shipping Process with Workflow Management

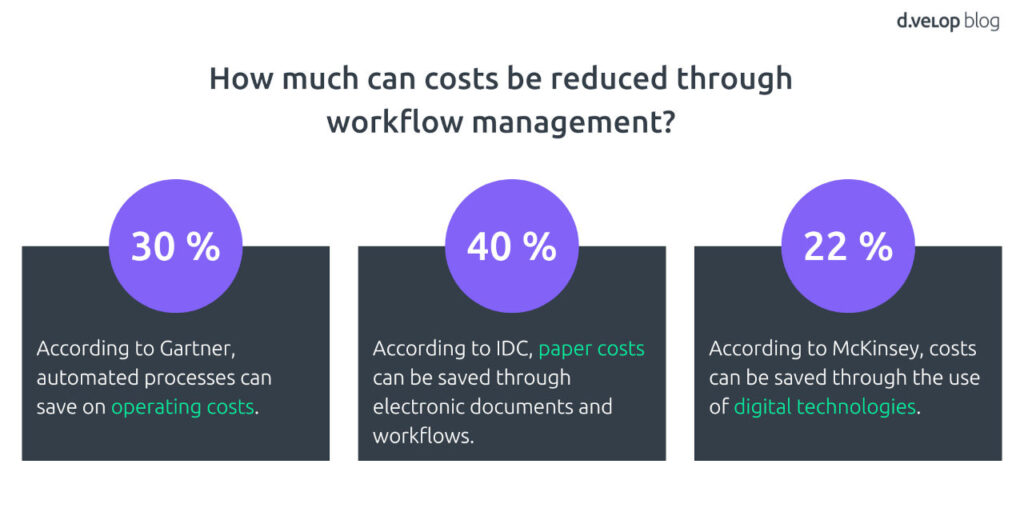

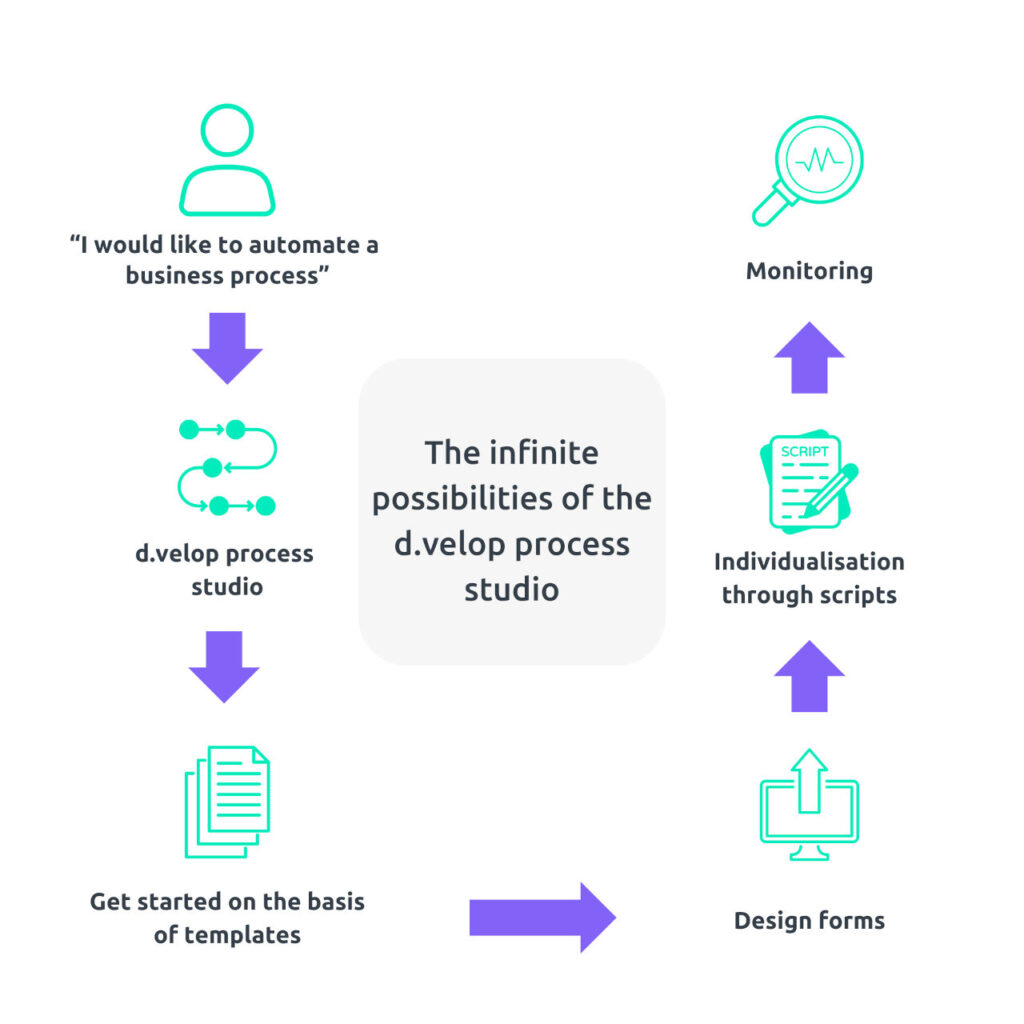

The automation of standard procedures, such as the shipping process, can be achieved through workflow management. Especially employees in the departments closest to the business process experience the pain of lacking automation most acutely. With d.velop process studio, complex processes are easily mapped out. In the editor, workflows can be represented using various elements. This form of no-code/low-code platform enables departments to automate their own processes. The processes can also be monitored and administered if necessary.

By modeling and optimising the shipping process, not only is long-term customer satisfaction increased and customer loyalty generated but also, the flow of information is accelerated. This relieves employees, who in turn have more time for other tasks. Workflow management offers numerous additional benefits: it minimises media disruptions and costs, increases transparency, and promotes collaboration through clear responsibilities. Moreover, it reduces sources of errors, simplifies workflows, boosts employee motivation, and shortens lead times. Overall, it contributes to efficiency improvement and enhances the overall performance of a company.

The shipping process is not the end of the chain. There are many business processes within a company that can be optimised – from returns, maintenance protocols to digital project approvals or innovation processes. Don’t hesitate any longer and unleash your optimisation potential with the d.velop process studio.

💻Book Software Demo

Experience the power of d.velop’s software with a personalised live demo, easily requested with just a few clicks. Watch as the software comes to life before your eyes and ask any questions you may have in real-time.