Maverick buying describes purchases that are made without the knowledge of the purchasing department, slowing down the procurement process. Get rid of maverick buying with a digitized procurement process and digitally link the individual steps from procurement application to the digital dossier.

According to a study entitled “Procurement 2020: Mean, Keen or Lean” by the Association for Supply Chain Management, Procurement and Logistics (BME) and the Boston Consulting Group, only a quarter of companies in Germany are below the critical maverick buying quota of 5%.

For us, this is a reason to take a closer look at the types, reasons and consequences of maverick buying – including remedies.

Why departments take procurement into their own hands

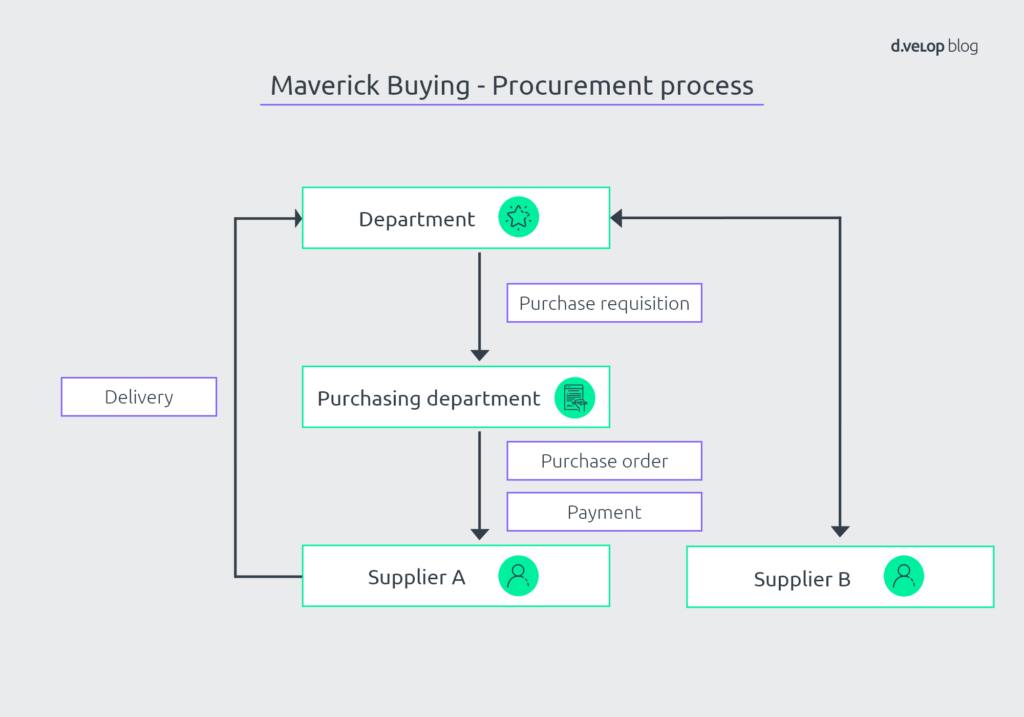

Before getting started with an analysis of the reasons for maverick buying, it will be helpful to take a brief look at the different types in the procurement process. Generally speaking, there are three different forms of maverick buying. The first type is when procurement occurs without any involvement from the purchasing department. The second type involves the purchasing department, but at a much later point in time. The third type simply does not use existing framework agreements.

When employees take procurement into their own hands, regardless of the type, this causes various problems and drawbacks for companies. But what exactly is it that makes employees act on their own – something many employers would actually like to see in other areas?

There is a wide variety of reasons for maverick buying, but usually the employees are not fully aware of the scope of the damage for the purchasing department and therefore also for their employer. Among the most common reasons are:

- Insufficient communication/transparency across processes and framework agreements

- Lack of trust in the purchasing department

- Insufficient speed in times of urgent demand

- Individual preferences and relationships with other manufacturers

- Incorrect assessment of competences within the company

- Lack of consideration of the overall context and the total cost

Benefits of maverick buying – can there be any?

The causes of maverick buying already indicate that the assessment of uncontrolled buying behavior within a company strongly depends on the observer. While the purchasing department strives to make the procurement process as structured as possible, the specialized departments primarily want to act fast, flexibly and to the benefit of employees. Conflict and debate are unavoidable. From a completely neutral standpoint, the following benefits and drawbacks result:

Benefits

- Speed

- Individuality & flexibility

- Taking advantage of special offers

Drawbacks

- Large number of suppliers

- Lack of cost transparency

- Higher procurement costs

- Higher maintenance costs

- Uncoordinated processes

- Shorter warranty periods

Controlling maverick buying without slowing down employees

Although maverick buying results in some benefits in daily work for the employees in particular, the drawbacks predominate for the company as a whole. According to Daniel Wiese, Partner at the Boston Consulting Group, a purchasing department should strive for the role as a central point of control within the company. Additionally, the purchasing department should substantiate control through the consistent application of all procurement means. This is a quite challenging task considering all the various points of view on the issue. Measures against maverick buying should therefore be taken considerately and with sure instinct.

In case of problems with maverick buying, the top priority should be to achieve transparency and clarity concerning the activities in the procurement process. Employees will only comply with internal requirements if they consider potential extra effort to be justified and can see the overall context. This primarily requires education. At the same time, the responsibilities within the company should be clearly defined and communicated. Despite all openness, it must not be forgotten to unmistakably position the purchasing department as the single point of contact for all procurement. It is not normally the task of the specialized departments to research suppliers, negotiate terms or issue purchase orders. Ultimately, the most important thing is to also make procurement processes as technically simple as possible – and digitization is the best option here…

How to achieve a maverick buying quota of <5% with a digitized procurement process

A procurement or purchase-to-pay process typically consists of five individual analog steps. These can be divided into further subprocesses: Prrocurement application, purchase order, incoming goods, invoicing and payment. If this process is analog and not considered in its entirety, some stumbling blocks will arise for the company at the respective transition points. This article has already described on of these stumbling blocks, i.e. maverick buying. According to the “Procurement 2020” study, digitization of the purchase-to-pay process therefore has the highest priority in Germany. Almost 70 percent of companies hope that digitization and more automation will provide opportunities for increased efficiency. In this context, reference is frequently made to Purchasing 4.0. In addition, more than 60 percent see great potential for digital solutions in the cooperation with suppliers.

The consistent design of procurement processes requires solutions digitally linking the individual steps. From procurement application to delivery note documentation and accounts payable processing to the digital dossier. The digitization of paper-based processes in companies represents a useful first step on the way to the fully digitized purchase-to-pay process.