The goods receipt is a crucial process in every company. It ensures that the received goods arrive in the correct quantity, with the expected quality, at the right time, and in the right place within the organisation. However, a paper-based goods receipt process is often time-consuming and prone to errors. Delivery notes must be recorded and assigned manually, which can lead to delays and mistakes. In this article, we focus on the digital procurement process in SAP and take a closer look at the SAP goods receipt.

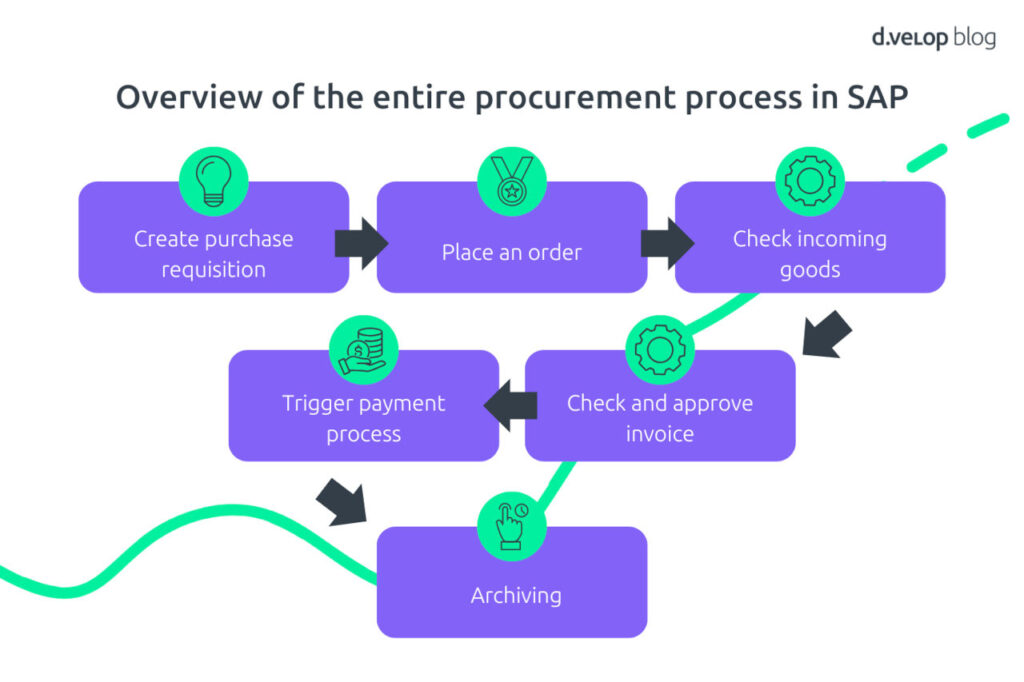

In previous articles, we have already examined the entire purchase-to-pay process as well as SAP purchase requisitions in more detail. This step is critical, as the timely delivery of the requested goods is the goal following a successful purchase order. Within the SAP procurement process, we now find ourselves in the area of goods receipt:

Checking Goods Receipt in SAP – The Right Goods, in the Right Place, at the Right Time

Goods receipt is all about quickly verifying whether the received goods have arrived in the correct quantity, with the expected quality, at the right time, and in the right place within the organisation. During this process step, the following questions must be checked and documented:

- Has the delivery/shipment arrived?

- Has the delivery been completed in full and without defects?

- Can the goods receipt be posted?

- Can the logistical invoice verification take place?

How can I assign the delivery note to the purchase order and subsequently link it to the invoice?

At first glance, this may seem like a demanding, yet manageable task. To get a better sense of the actual complexity involved in checking and verifying goods receipt, let’s consider a simple example:

Case Study: Goods Receipt in a Multi-Location Environment

A company places an order for goods through its headquarters in Frankfurt. The goods are then delivered to Frankfurt as well as to branch offices in Munich and Hamburg. At each location, the goods receipt is checked and confirmed on the delivery note. Only once all delivery notes have arrived at the headquarters can the goods receipt be recorded—albeit with a delay.

Even relatively minor factors, such as having multiple company locations, can significantly impact the goods receipt process in SAP. It’s easy to imagine how error-prone and inefficient a non-automated goods receipt process can become. The following section explores the additional challenges and risks hidden within a paper-based process.

Paper-Based Goods Receipt: Risks Lurking at Every Turn

A traditional, paper-based goods receipt process in SAP involves numerous manual steps. It begins with checking the delivered goods for completeness and quality. If everything is in order, the signed delivery note is placed in a tray and forwarded to the purchasing department or sent via internal mail to the company’s headquarters. This marks the first delay in the process.

Once the documents finally reach the correct department, the goods receipt is manually entered. The responsible employee must locate the correct purchase order in SAP and post the goods receipt. Due to the high level of manual data entry, this stage of the process becomes a major source of errors, which can have far-reaching consequences for other departments, such as finance and accounting.

Next, the delivery note must be manually matched to the original purchase order. Documents need to be stored physically within easy reach of staff for quick access, which inevitably leads to space and coordination issues.

Even after the goods receipt has been posted, the process remains labour-intensive. Typically, spreadsheets must be maintained to track the current status of goods receipts. Overall, a non-automated goods receipt process is extremely time-consuming and error-prone. Throughout the entire process, there is a constant risk of losing delivery notes, documents, or handwritten notes. All of this is reason enough to consider switching to an automated goods receipt process.

Digital Goods Receipt: Capturing and Posting Deliveries in Real Time

Unlike the traditional process, in an automated workflow, delivery notes are scanned and captured immediately upon receipt of goods. Using OCR (Optical Character Recognition), the delivery notes are read, and all relevant data—such as supplier, purchase order number, and delivery quantities—are automatically transferred to the SAP system. The data from the delivery note can then be digitally forwarded via workflows to the responsible colleagues for further processing. At the same time, the delivery note is archived in a legally compliant and audit-proof manner.

One major advantage of the digital process is the direct link to the underlying purchase order. During scanning, the purchase order and goods receipt are automatically matched and linked. The line items from the order are compared with the goods received, allowing warehouse or procurement staff to instantly see whether the delivery is complete. The goods receipt can then be posted.

For raw materials that are critical to production, a multi-level approval process can be implemented, ensuring that only authorised personnel with full process oversight can post the goods receipt. This gives all stakeholders involved in the process a clear and qualified overview of the current goods receipt status.

In just a few automated steps, the SAP goods receipt is captured and posted.

The Advantages of Digital Goods Receipt Control at a Glance:

- Immediate overview of incoming goods

- Instant verification and direct posting of deliveries in SAP

- Acceleration of downstream processes, especially logistical invoice verification

- Automatic archiving of delivery notes

Now that the benefits are clear, all that’s missing is the right solution. With d.velop delivery note for SAP ERP, you maintain full visibility of your goods receipt and are instantly informed when a delivery arrives at a decentralised warehouse. The delivery can be checked, and the corresponding material document can be created and posted directly in SAP. You can find all the details on our page about the digital procurement process in SAP.

A Few Steps to Automated Procure-to-Pay Processes in SAP

Gain insight into what a digital procurement process looks like and its benefits over the traditional process.