Digital Procurement Processes – and How Your Business Can Benefit

Challenges in Procurement

Nothing in procurement is as it used to be. And companies that have already switched to digital workflows in their procurement departments agree: that’s a good thing. Procurement processes are constantly evolving. Import restrictions, international legal reforms, supply chain laws, political crises – these are challenging times for corporate buyers. Digitalisation, however, has enabled fast and efficient workflows that allow procurement professionals to respond effectively to unpredictable market fluctuations. With the right technologies and software, they are well-equipped to succeed now and in the future.

Fragile Availability of Raw Materials and Goods

In a world where the global availability of raw materials and goods is more fragile – and more critical – than ever, analogue procurement processes are no longer competitive. In contrast, new technologies have revolutionised procurement in recent years. Automation saves time and creates space for more strategic, value-adding activities. Digitalisation not only enables more efficient, automated processes, but also improves data analysis – allowing for better-informed decisions based on extracted procurement KPIs.

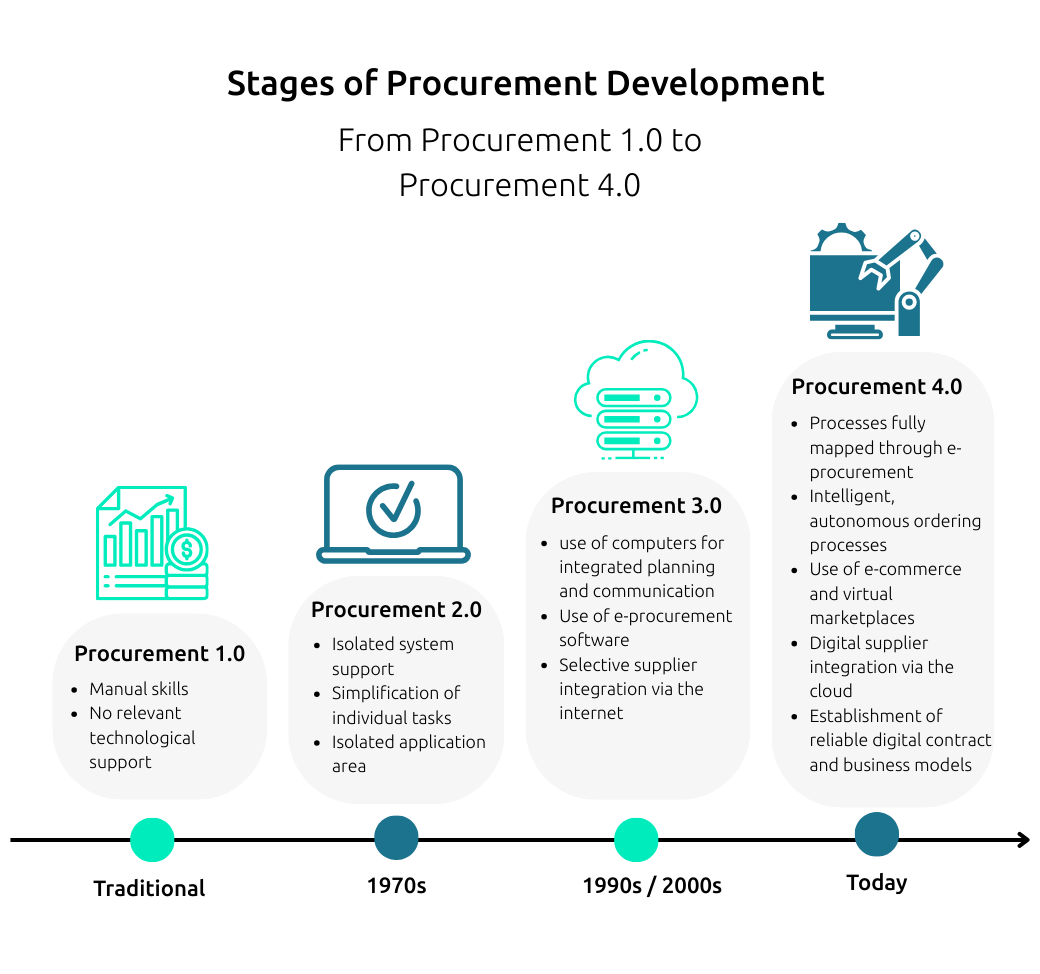

Procurement 4.0 Is the Present and the Future

Since the 2010s, automated processes have emerged under the umbrella of Procurement 4.0. These are characterised by autonomous digital ordering systems based on big data analytics. Virtual marketplaces have transformed the way goods are traded. Cloud-based supplier integration marks a quantum leap, enabling companies to seamlessly incorporate suppliers and partners into their business processes. And these are just a few examples of the groundbreaking workflows found in modern, digitalised procurement departments.

Continuously Rethink and Adapt Procurement Processes

That’s why it’s essential for companies to continuously review and adapt their procurement processes to meet new demands. Those who fail to digitalise their procurement risk falling behind.

- 15 % additional costs incur in companies on average due to maverick buying

- 75 € are the average process costs per purchase order.

- 87 % of procurement leaders believe that digitalisation will improve procurement.

Definition: What Is Procurement in a Company?

The term procurement in a business context refers to the process of acquiring goods and services to support the company’s operational activities. Procurement includes not only identifying needs, but also selecting suitable suppliers and negotiating prices. It also involves agreeing on contract terms, as well as managing orders and payments. The goal of procurement is to meet the company’s requirements in terms of quality, cost, and delivery time. At the same time, it ensures that the purchased goods and services meet the necessary standards and maximise value for the organisation.

Which Laws Affect Corporate Procurement?

Procurement professionals in companies must consider a wide range of laws and regulations. Whether in strategic or operational procurement, both national and international guidelines must be followed – covering political, financial, environmental, social, and safety-related aspects. Violations can result in severe penalties. That’s why it is essential for procurement processes to be legally compliant, and for procurement departments to stay informed about the latest legal developments in the fields of purchasing and logistics. The most important applicable laws and regulations – many of which are subject to change – include:

Trade Policy and Trade Agreements

Changes in trade policy or international trade agreements can impact the procurement of raw materials, products, and services from other countries. For procurement teams, it is essential to always have a Plan B in place in case Plan A becomes unavailable.

Procurement Legislation

Laws and regulations related to the procurement of goods and services – such as those concerning tenders, supplier qualification, or sustainability requirements – can significantly impact the purchasing process. One example is the German Supply Chain Due Diligence Act, which came into force on 1 January 2023. It requires German companies above a certain size to ensure compliance with human rights and environmental standards throughout their supply chains.

Customs and Import Regulations

Changes in customs and import regulations – such as trade embargoes – can affect the procurement of goods from abroad. That’s why it is always advisable to have an alternative sourcing strategy for essential raw materials and goods. This helps prevent supply disruptions and safeguards the continuity and viability of the business.

Sustainability and Environmental Protection

Sustainable procurement is becoming increasingly important for many companies. For example, they aim to reduce their CO₂ emissions and environmental footprint. In addition to voluntary sustainability goals, there are also legally mandated targets – such as the climate goals that each country must meet. Another example is the EU regulation on sustainability disclosure, which requires certain companies with more than 500 employees to report on their environmental, social, and governance (ESG) performance. This includes information on greenhouse gas emissions, pollution, working conditions, and human rights.

Labour and Social Law

Procurement departments must ensure that their suppliers and service providers comply with applicable labour and social legislation. This helps minimise the risk of human rights violations and other breaches of social responsibility.

Data Protection and IT Security

When procuring IT products and services, procurement departments must ensure compliance with data protection and IT security regulations. This is essential to reduce the risk of data breaches and cyberattacks.

What Are the Responsibilities of Procurement in a Company?

Procurement is a key function responsible for acquiring goods and services within a company. However, procurement is not merely an operational process – it plays a crucial role in ensuring the smooth running of business operations. Procurement professionals are also responsible for developing procurement strategies and overseeing procurement controlling to secure the supply chain in the long term and enable forward-looking inventory management. This overview highlights some of the core responsibilities of a procurement department:

- Timely procurement: Supplying production with raw materials and goods; commissioning services (including delivery scheduling for warehouse materials)

- Monitoring delivery times based on supplier confirmations

- Negotiating prices with suppliers

- Establishing framework agreements

- Requesting quotations, calculating costs, and keeping an eye on finances

- Placing orders and coordinating the transport of goods

- Checking invoices

- Maintaining master data

- Monitoring stock levels

- Managing complaints and returns

Differences Between Strategic and Operational Procurement

There are two distinct types of procurement processes: strategic and operational procurement. They differ in their goals, focus areas, and responsibilities. However, they are closely connected and must work together to achieve a company’s overall procurement objectives.

Key Differences Between Strategic and Operational Procurement:

Objectives: Strategic procurement aims to optimise purchasing activities and make long-term decisions that lead to cost savings and competitive advantages. Operational procurement, on the other hand, focuses on meeting short-term needs and ensuring that materials and services are procured on time and within budget.

Focus: Strategic procurement concentrates on analysing market trends, developing sourcing strategies, identifying suppliers, negotiating contracts, and assessing supply chain risks. Operational procurement is primarily concerned with day-to-day order processing, managing supplier relationships, and resolving delivery issues.

Responsibilities: Strategic procurement is responsible for planning and implementing procurement strategies and identifying suitable suppliers. Operational procurement handles order processing, managing purchase orders, and monitoring deliveries.

| Strategic Procurement | Operational Procurement |

|---|---|

| Needs analysis | Request for quotation (RFQ) and comparison |

| Supplier evaluation and selection | Escalation management in case of delivery issues |

| Negotiation of contract terms | Purchase order creation and order confirmation |

| Identification of risks in the supply chain | Tendering and bidding processes |

| Contractbeheer | Deadline monitoring and delivery tracking |

| Supplier development | Goods receipt inspection |

| Cost management | Invoice verification and processing |

| Sustainability management | Returns management |

| Controlling and Reporting | Master data maintenance |

| Innovation management | Inventory management and optimisation |

Which Procurement Processes Exist?

There are a wide variety of procurement processes used in both the service and materials sectors of companies. Depending on specific needs and requirements, these processes can vary. Some of the most common procurement processes include:

- Demand identification and planning: Identifying needs and requirements from various departments within the company.

- Supplier evaluation and selection: Assessing and selecting suppliers based on criteria such as quality, price, delivery time, and reliability.

- Request for quotation and evaluation: Gathering information about specific products or services, including comparison and assessment.

- Price negotiations and contract drafting: Aiming to secure the best possible terms for the company when dealing with suppliers.

- Purchase order creation: Issuing orders for required goods or services, considering supplier agreements, budgets, and delivery times.

- Order monitoring: Tracking the order process to ensure timely delivery and expected quality.

- Claims and returns management: Receiving and reviewing complaints and managing the follow-up process.

- Invoice verification and processing: Checking and approving incoming invoices to ensure prices and quantities match the orders.

- Inventory management: Managing stock levels and replenishing them through procurement.

- Cost analysis and optimisation: Reviewing market prices and renegotiating supplier terms.

- Strategic planning and procurement development: Identifying needs and sourcing options to ensure long-term, cost-effective, and high-quality supply of goods and services.

What are the biggest challenges in procurement?

The acquisition of goods and services plays a crucial role in a company’s value chain. However, there are various challenges and issues that can arise during the procurement process, which may affect the efficiency and profitability of the business.

Successful Procurement Management: Identifying and Resolving Issues

These issues range from the sourcing of products and services to contract negotiations and collaboration with suppliers. It is therefore essential to identify and address these problems to ensure successful procurement management. The main sources of problems lie in the following areas:

- Manual data entry and processing: Procuring goods and services requires extensive documentation and data handling, such as purchase orders, order confirmations, and supplier invoices. When this process is carried out manually, it becomes time-consuming and prone to errors. This includes manually checking delivery dates in order confirmations and, if not automated, converting SAP purchase requisitions into purchase orders. It also involves maintaining master data, recording and matching order confirmations, and creating purchase orders.

- Unstructured document archiving: A common issue in non-digitalised companies is the use of complicated folder structures based on various criteria. At the other extreme, documents are stored in physical folders. Document types that need to be archived include enquiries, quotations, purchase orders, order changes, reminders, order confirmations, delivery schedules, call-offs, delivery notes, contracts, framework agreements, incoming invoices, correspondence, and supplier complaints.

- Lack of transparency: A manual procurement process can make it difficult to keep track of current orders, deliveries, and payments, often leading to delays and inefficiencies.

- Collaboration difficulties: Without digitalisation, sharing information and documents with other departments involved in procurement can be challenging, resulting in delays and miscommunication.

- Supplier management challenges: Effective supplier management requires good communication, evaluation, and monitoring. Without digital tools, collecting and managing supplier information and assessments becomes difficult.

- Lack of automation: Digitalising the procurement process allows for the automation of many tasks, such as ordering, payments, and deliveries. Manual processes are time-consuming and error-prone.

- Limited analytical capabilities: Without a digital procurement solution, companies may struggle to collect and analyse data to make informed decisions. A digital solution helps gather and evaluate data to improve procurement processes and increase efficiency.

- Delayed deliveries: Late deliveries disrupt production and affect all downstream processes. Delays can jeopardise on-time project completion and may even lead to contract termination.

- Missing information or documents: When documents are not where they should be, it hinders traceability and audit compliance. Such losses also lead to a lack of transparency.

- Outdated structures: Where rigid processes prevail and no development occurs, there is often a lack of acceptance of digitalisation. In the long term, companies that cling to analogue workflows are likely to disappear from the market.

- Cumbersome approval procedures: Complicated approval processes can delay project implementation and innovation, thereby reducing competitiveness.

- Missing signatures: In analogue processes, documents are often left unsigned due to the inconvenience. However, without a signature, documents lack legal validity. Electronic signatures can be used universally and, as qualified electronic signatures (QES), are legally binding in court.

- Lack of collaboration software: When documents still need to be sent by fax, post, email, or internal mail, a lot of time and money is wasted. A central digital repository in a document management system (DMS), accessible from any workstation, provides a solution.

- Supply risks: Every company faces supply risks. These include non-delivery due to insolvency, unusable goods due to quality issues, trade restrictions due to political decisions, or price fluctuations making purchases unprofitable.

Procure to Pay White paper

A Few Steps to Automated Procure-to-Pay Processes in SAP

To ease the transition to a completely automated procurement process, you’ll find step-by-step instructions in this white paper about how you can automate your procurement process: from analysing your current situation to digitizing individual subprocesses. Gain insight into what a digital procurement process looks like and its benefits over the traditional process.

Agenda

- Map out the procure-to-pay process for your Organization

- Analysing your current situation

- The solution: Digital procurement process in SAP

- Advantages at a glance

Why Digital Processes in Procurement Are Important

Digital processes in companies have a wide-ranging positive impact on business efficiency. One of the most significant benefits is the substantial increase in efficiency achieved through the use of digital technologies. Companies can automate many manual processes, leading to a more streamlined handling of procurement activities. This includes, for example, the electronic sourcing of goods and services, automated order processing, and electronic invoice handling.

More Cost-Effective Procurement Processes

As efficiency increases, so do cost savings. Automation in procurement—such as through the use of e-procurement systems—enables faster price comparisons, which can lead to more favourable purchasing prices. Additionally, reducing paper and printing costs through digital document processing can contribute to further savings.

Improved Data Quality for Procurement Optimisation

A third key aspect is the improvement of data quality. Digital processes enable better data collection and processing. By using digital tools and systems, data can be captured and processed more quickly and accurately, which increases data precision.

Maverick Buying: Aggregated Procurement

Based on this data, so-called maverick buying becomes possible. This is a strategy in which a buyer combines the purchase of goods or services from multiple suppliers to achieve better prices or conditions. This type of procurement is also referred to as aggregated or joint purchasing.

Key Digital Processes in Procurement 4.0

The term Procurement 4.0 refers to the use of innovative technologies to automate and optimise the procurement process. It forms the foundation for a new, digital business process management system in the procurement sector. The most important processes in Procurement 4.0 include the automation of ordering, the digitalisation of procurement workflows, and the implementation of intelligent decision-making systems. Together, these processes aim to make procurement more efficient and transparent. Some key functions include:

E-Procurement

This refers to the digital procurement process, where companies can select suppliers online, place orders, and pay invoices. E-procurement systems can automatically generate purchase orders, obtain approvals, and track deliveries.

E-Sourcing

E-sourcing tools help companies make the procurement process more efficient by automating the identification of suppliers, comparing quotations, and selecting the best offer.

Supplier Relationship Management (SRM)

SRM systems help companies effectively manage and optimise their supplier relationships. They enable businesses to evaluate supplier performance and manage their suppliers strategically.

E-Invoicing

E-invoicing (Electronic Invoicing) refers to the electronic exchange and automated processing of electronic invoices. When a company is able to send, receive, and process invoices automatically, this is referred to as e-invoicing.

E-Auctions

E-auctions enable companies to create competition among suppliers and achieve the best price for a product or service.

Analytics and Reporting

Analytics and reporting allow companies to collect and analyse data to make better decisions in the procurement process. By using data analysis, they can identify trends and uncover potential savings.

Contractbeheer

Contract management software helps companies optimise their contract management processes. This includes managing supplier contracts more efficiently and ensuring that agreed terms and conditions are adhered to.

Benefits of Digital Procurement Processes for Accounting

The digitalisation of procurement processes offers numerous advantages—not only for procurement itself, but also for accounting. These include the simplification of payment transactions and invoice processing through the automatic transfer of invoice data into accounting software. Invoices can also be processed and paid more quickly, leading to more efficient cash flow management. Digital document management systems (DMS) support this by enabling the electronic archiving of invoices and receipts. This reduces paper consumption as well as printing and storage costs.

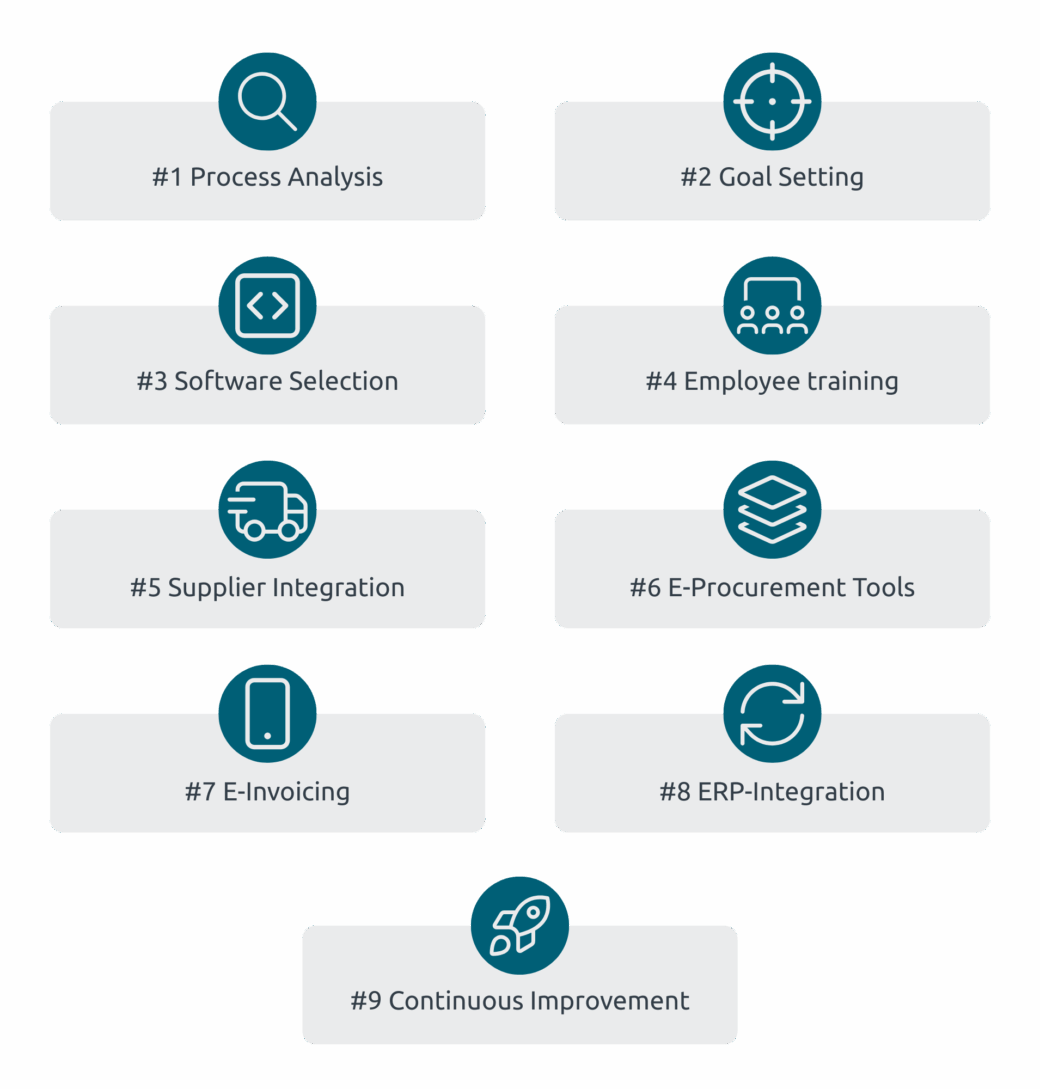

How to Digitalise Your Procurement in 9 Steps

The number of companies recognising the benefits of digitalising their procurement processes is steadily increasing. They are turning to innovative technologies to reduce costs, boost efficiency, and enhance competitiveness. Successful digitalisation of procurement requires a comprehensive strategy and careful planning. In this section, we present nine steps that can help companies digitalise their procurement and make a significant contribution to overall business success — from identifying business processes and integrating software solutions to monitoring key performance indicators.

- Analyse Current Procurement Processes: Review existing manual processes and identify areas that can be digitalised.

- Define Clear Objectives: Set clear goals for digitalising procurement, such as cost reduction, process automation, or improved data quality.

- Select Suitable Software: Choose procurement software that meets your requirements and integrates seamlessly with your existing systems.

- Train Employees: Provide training for your staff to prepare them for the new software and the changed workflows.

- Integrate Suppliers: Invite your suppliers to participate in the digital procurement process to ensure smooth collaboration.

- Implement E-Procurement Tools: Use e-procurement tools to automate ordering and simplify the purchase of goods and services.

- Introduce E-Invoicing: Implement e-invoicing to receive and process invoices electronically.

- Enable Data Exchange with ERP Systems: Integrate your procurement software with your ERP system to automatically synchronise data and reduce manual work.

- Continuous Improvement: Continuously monitor the procurement process and look for opportunities to improve. Analyse data and use insights to further optimise workflows.

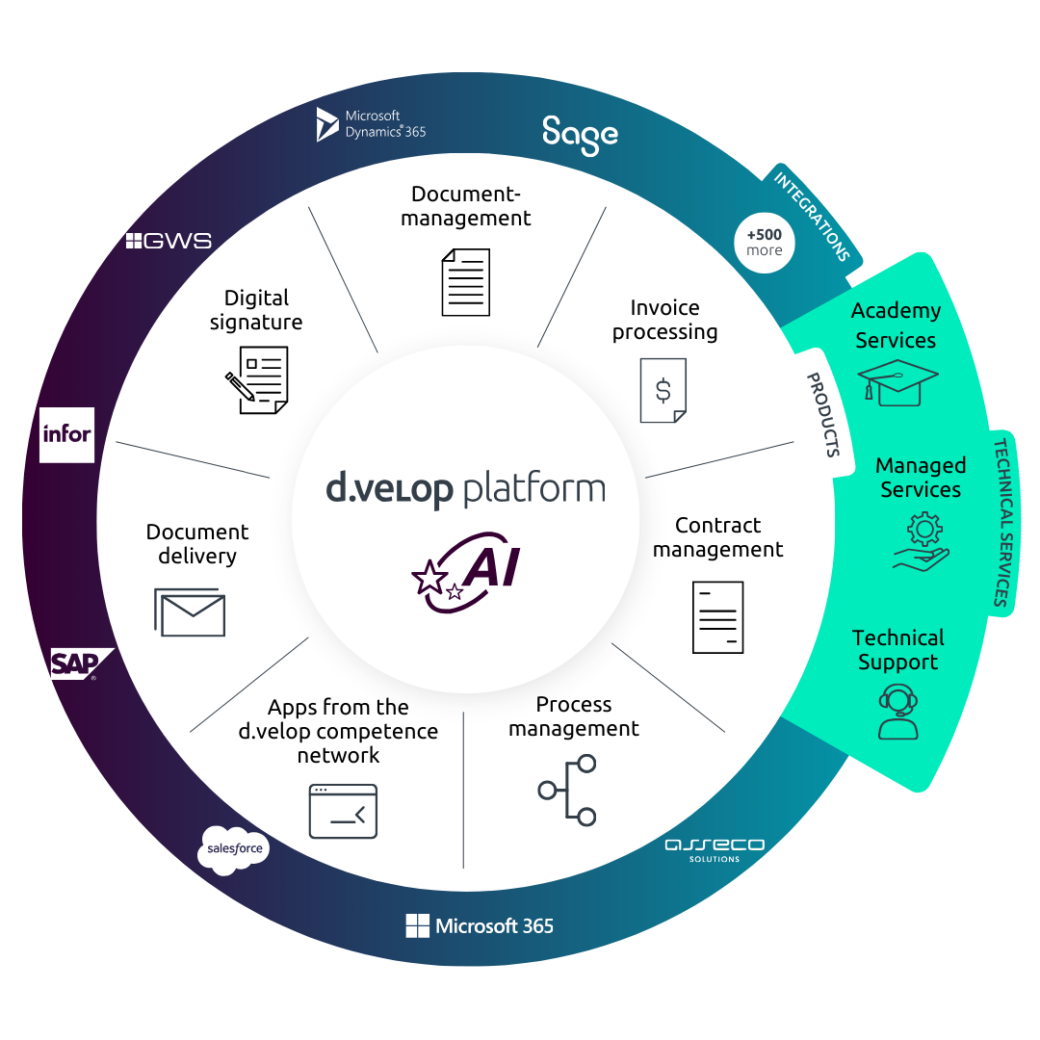

Overview of d.velop Products for Procurement

Digitalising procurement is an important step towards increasing efficiency and reducing costs. The d.velop platform offers a range of products that enable you to quickly and easily implement digital business processes tailored specifically to the needs of procurement departments.

1. d.velop documents | Document Management System (DMS)

With the document management system d.velop documents as a digital archive, you can digitalise your business processes and take a major step towards transforming your procurement. Archive all your documents—such as delivery notes, quotations, supply contracts or receipts—in one central location. This way, no document ever gets lost again. And even better: they are always available to everyone, everywhere.

2. d.velop sign | Digital Signature

The digital signature significantly simplifies the signing of documents—both within companies and between international contracting parties. Gone are the days of media disruptions, where contracts had to be printed, signed, scanned, and emailed to all parties involved. With d.velop sign, signing documents takes just seconds. Legally compliant and cost-effective.

3. d.velop invoices | Digital Invoice Processing

With d.velop’s digital invoice processing, you can not only quickly capture and match master data, but also carry out fast, automated invoice verification. d.velop invoices integrates seamlessly with other systems (ERP, accounting, and inventory management) and enables audit-proof archiving.

digital invoice processing White paper

Digital invoice processing – 9 arguments for your IT department

Anyone who says it’s hard to get colleagues excited about digital processing of accounts payable probably just needs the right arguments. The advantages of accounts payable processing for users and companies are obvious.

The white paper will help you to dispel reservations. Win over even the skeptics and doubters for the introduction of a digital accounts payable processing system.

4. d.velop contracts | Digital Contract Management

With d.velop contracts, you’ll never lose track of your contracts or cancellation deadlines again. Benefit from complete transparency and efficiency, as this solution allows you to create and manage contracts much faster. What’s more, you’ll never misplace a contract again – on the contrary: your contracts are digitally available across departments.

5. d.velop postbox | Digital Mail Delivery

With the digital mailbox, delivering procurement-related documents becomes simple, fast, and hassle-free. d.velop postbox saves both time and money by eliminating the need for paper and postage. It is also legally compliant, meeting all data protection and security standards. And best of all: no more annoying paperwork. Employees, partners, and customers receive everything digitally.

Seamless Integration of d.velop Software into Existing Systems

d.velop software offers interfaces and integrations with a wide range of third-party systems. By integrating d.velop solutions, companies using other platforms as their primary interface can seamlessly embed and automate their business processes. This eliminates the need for employees to switch between different systems and makes it much easier to share information. It simplifies collaboration, enables better data analysis, and improves customer satisfaction by speeding up response times. The Gartner Magic Quadrant for Content Services Platforms confirms d.velop’s strong integration expertise – whether with ERP, CRM, or other leading applications.

Conclusion: Digital Procurement as an Opportunity

Digitalisation enables procurement processes to become more efficient and transparent. Companies should recognise and leverage the potential that digital procurement offers. This means saving time and costs while achieving higher quality and greater flexibility in purchasing. Moreover, employees gain more time for value-adding activities. By automating procurement processes, they can focus on tasks that deliver greater value to the business. This allows companies to deploy their workforce more effectively and enhance their competitiveness.

Procurement Digitalisation on the Blog

Learn More About Digital Procurement

The d.velop blog regularly features background articles, insights, and expert contributions on digital procurement departments, legal aspects, current market developments, and much more.

Frequently Asked Questions and Answers about Digital Procurement Processes

In companies, there are various procurement processes, such as needs assessment, supplier selection, price negotiation, ordering, and invoice verification. These steps can be combined differently depending on the company.

Digital procurement processes enable faster and more efficient order handling. They also allow for better control and monitoring of deliveries and inventory. In addition, automation and digitalisation help reduce errors and achieve cost savings.

Procurement 4.0 is an innovative procurement strategy based on the digitalisation and networking of procurement processes. It involves the use of technologies such as artificial intelligence, big data, and cloud computing to increase efficiency and transparency in procurement and to optimise the supply chain.

First, you should assess your current manual processes. Then, identify potential digital solutions. After that, you can implement suitable tools or software and ensure that your employees receive appropriate training.

There are various technologies that companies can use to digitalise their procurement processes, such as e-procurement systems, digital catalogues, electronic ordering and invoicing, and automated inventory management systems.

Contact & Consultation

We Connect Data and People – And Look Forward to Hearing from You.

Curious? We’d be happy to show you our software.

Simply request a live demo.